Frequently asked questions about the PDE bridge (FAQs)

The ORIGINAL PDE bridge from 07eins

FAQs - PDE Bridge

What is the "ORIGINAL PDE Bridge" and what is its main purpose?

The "ORIGINAL PDE Bridge" is one of 07eins developed repair component especially for 2.5-liter TDI engines (5-cylinder) as found in the VW T5. Its main purpose is to repair the pump-nozzle elements (PDE). to center them permanently and stress-free in their correct position in the cylinder headThis prevents the problem of "slanted" PDE elements and the resulting cylinder head damage caused by insufficient lubrication due to leaks.

For which specific vehicle models and engines is the "ORIGINAL PDE bridge" compatible?

The "ORIGINAL PDE bridge" is suitable for VW 2.5-liter TDI engines (5-cylinder) especially for those in the VW T5 (Transporter, Multivan, Caravelle, California) up to model year 2010. It is compatible with all engine code letters (MKB) of the 2.5-liter TDI engines in the VW T5.

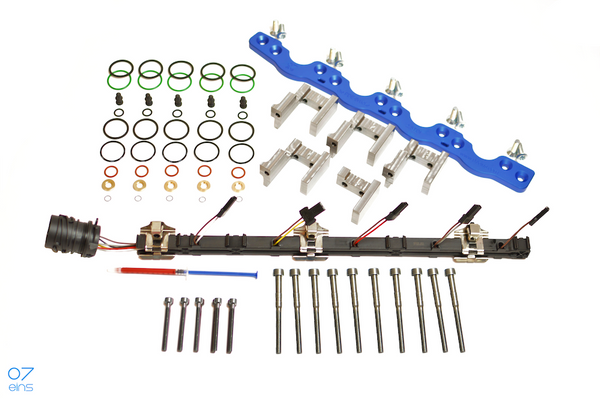

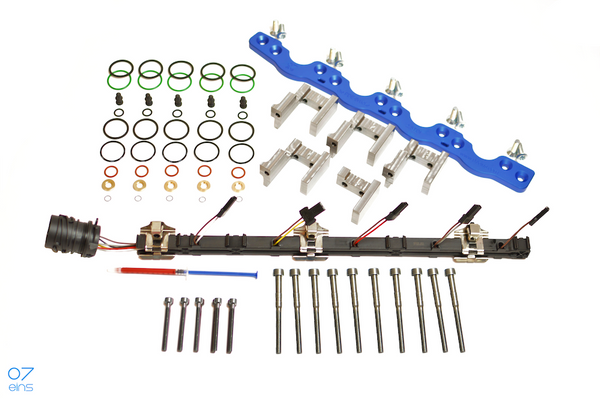

Which key components are included in the typical scope of delivery of an "ORIGINAL PDE bridge"?

The typical Scope of delivery of an "ORIGINAL PDE bridge" includes a flexible aluminum cross strut, precision-manufactured tool steel holders (e.g. 5 pieces for a 5-cylinder engine), fastening screws and fastening clamps for the electrical connection strip of the PDEs.

How does the "ORIGINAL PDE bridge" solve the problem of skewed PDE elements?

The "ORIGINAL PDE bridge" mechanically stabilizes the PDE elements and prevents their unwanted movementwhich is a systemic problem of the original factory design. This directly addresses the root cause of the problem - cylinder head seat wear - and aims to restore proper function and prevent further damage.

Can the "ORIGINAL PDE bridge" be used both to repair existing damage and to prevent future problems?

Yes, the "ORIGINAL PDE bridge" is suitable for a dual purpose It is designed to repair cylinder heads that are already damaged and to prevent damage to the injector sealing surfaces (cylinder head damage) that could jeopardize their function.

What are the estimated costs of a repair with the "ORIGINAL PDE bridge" compared to a complete cylinder head replacement?

The material costs for the "ORIGINAL PDE bridge" are 429 EUR, or between 479 - 1,149 EUR when purchased as a set with reinforced VITON gaskets and a wiring harness. The estimated total repair costsincluding materials, installation and testing, are approx. 1,000 - 1,500 EUR. This is significantly less than a cylinder head replacement, which can cost around EUR 4,000 - 4,500.

What are the long-term benefits and user experiences with the "ORIGINAL PDE bridge"?

The "ORIGINAL PDE bridge" offers a permanent solution to the root cause of the problem, with extensive positive feedback from the field and successful installation in tens of thousands of vehicles. Workshops and customersusing the system are "totally convinced" and report the elimination of "all problems", proving its reliability and effectiveness as a long-term solution.

Is the installation of the "ORIGINAL PDE bridge" a simple DIY task, or is a professional installation recommended?

Although the 07eins-bridge itself is described as very easy to install due to its modular design, the entire repair process is demanding. It can be carried out by experienced DIY enthusiasts in just a few hours (see our installation instructions), but due to the complexity of accessing the work area and carrying out the necessary preparatory and accompanying tasks, a professional installation in one of the over 400 partner workshops of 07eins in Europe recommended.

What accompanying measures and component checks are necessary during the installation of the "ORIGINAL PDE bridge"?

For a successful and long-lasting repair, it is crucial to check several other components during installation and replace them if necessary. These include replacing the PDE seals (reinforced VITON seals are strongly recommended), the careful deburring or straightening of existing "nicks/wear marks/grooves" in the PDE channels of the cylinder head and the replacement of certain bolts (expansion bolts and grub screws) using high-strength threadlocker. A professional inspection and overhaul of the PDE elements is also recommended.

What is the significance of the flexible aluminum alloy used in the "ORIGINAL PDE bridge"?

The specific aluminum alloy of the 07eins-connecting rod makes it possible to compensate for existing height tolerances without introducing increased tension into the cylinder head. This design ensures precise and tension-free fixing of the PDE elements. You can find details in our blog post "Aluminum PDE bridge: Tension-free fixing is better than rigid fixing".

Retractable content

Is my vehicle also affected?

It affects all diesel engines with pump-injector units (PDE) that are bolted on one side (model years 1998 to 2010).

How do I notice that something is wrong with my vehicle?

- Starting problems with the engine, especially at cold start and when the engine is particularly hot

- Unsteady idling (speed fluctuations) or sporadic misfires at low engine speeds ("choking" of the engine)

- Diluted engine oil ("engine oil build-up") due to diesel mixture (oil level rises over time)

- Lack of / low oil pressure if the bearing shells are already worn due to diesel in the oil

- Stalling of the engine in city traffic

- Loss of power

- Loss of compression

Further important information under: "What happens if I do nothing about it and do not install a bridge for the pump/nozzle unit (PDE)?"

What happens if I do nothing about it and do not install a bridge for the pump-nozzle unit (PDE)?

- In all diesel engines with pump-injector units (PDE) that are bolted on one side, the PDEs work their way more and more into the cylinder head over the course of the running time.

- As a result, leaks cause diesel to mix into the engine oil.

- The lubricating effect of the engine oil is significantly reduced, which over time leads to complete engine failure.

Details on the cause of the damage and the functional principle of the PDE bridge can be found in our video:

Functional principle of the PDE bridge (pump-nozzle bridge) to prevent cylinder head damage

Do I need the PDE bridge or the PDE body holders?

- The PDE bridge has been specially developed for VW 5-cylinder 2.5 liter TDI engines with a pump-injector unit.

- The PDE body holders are a more universal further development of the PDE bridge, which is suitable for all 3-cylinder, 4-cylinder, 5-cylinder and 10-cylinder VAG/VW TDI engines with a pump-injector unit.

- Customers with a VW 5-cylinder 2.5 liter TDI engine with a pump-injector unit therefore have the choice between the PDE bridge and the PDE body mounts. Most of these customers opt for the PDE bridge as they have more experience with it.

What experience is there?

- The PDE bridge has already been successfully installed more than 10,000 times in VW 2.5 liter TDI engines.

- The mileage usually increases by 100,000 km or more.

How does the PDE bridge work for engines with pump-injector units (PDE) installed on one side?

- Compared to the factory-fitted tensioner shoes, which are only fixed on one side, the PDE bridge ensures that the PDEs are fixed more evenly.

- This ensures a more even fixation of the PDEs, especially when the sealing kits are replaced at the same time and the reinforced 07eins-VITON sealing rings at the same time, this prevents the PDEs from working their way back into the cylinder head and the familiar problems caused by leaks from occurring.

Details on the origin of the damage and the functional principle of the PDE bridge can be found in our video:

Functional principle of the PDE bridge (pump-nozzle bridge) to prevent cylinder head damage

How does the installation work?

- Our products are installed without any modifications/work on the engine/cylinder head. Original screws and fixing points are used. Service-related removal for further maintenance work can be carried out without any problems due to the multi-part design.

- The factory-fitted clamping shoes 2 to 5 for the pump/nozzle units are replaced by the PDE bridge elements.

- Professional inspection and disassembly of the pump-nozzle elements requires the use of new expansion bolts and sealing elements. If required, selected complete sets of consumables of excellent quality are available at the following link:

PDE bridge (complete set)

- The installation can either be carried out by any vehicle workshop or you can do it yourself if you have the necessary technical knowledge.

Where can I find a suitable garage?

Suitable automotive workshops for installing the 07eins PDE bridge with our installation workshop finder:07eins Partner workshops

Can I carry out the installation myself?

Experienced screwdrivers can also install the 07eins pump-nozzle products themselves.

The corresponding video and PDF installation guides contain all the important information with step-by-step instructions: own installation (do it yourself)

What else is useful?

- We always recommend replacing all seal kits of the pump-nozzle units, especially the uses of the 07eins reinforced VITON seals.

You can find a complete set in our store:

PDE bridge (complete set)

- We also recommend completely replacing the wiring harness at the same time. You can find them for the 2.5 TDI engine here in our store: VW T5 wiring harness

PDE bridge VW T5 2.5 TDI

The original PDE bridge, already 2015 from 07eins and installed in 10,000 vehicles since then - is now a tried-and-tested means of repairing damaged cylinder heads and preventing damage to the injector sealing seats that could jeopardize their function.

-

COMMUNITY

popular in the German-speaking VW T5 community

-

TRUST & QUALITY

German development and product quality already installed in over 5,000 VW T5 vehicles

-

INSTALLATION & SERVICE

over 400 partner workshops

in Europe

The ORIGINAL PDE bridge

-

PDE bridge

Buy PDE bridgeThe ORIGINAL:

1x Flex connecting strip

5x steel clamp mounting screws and

Fixing clamps for the electrical connection strip

-

Complete set

Buy complete setThe 07eins-complete set:

1 x ORIGINAL PDE bridge (pump-nozzle-unit bridge)

5 x reinforced VITON gasket set

1 x PDE mounting kit for 5-cylinder

for VW T5 2.5 TDI (all code letters)

-

Ultimate set

Buy Ultimate-SetThe 07eins-Ultimate" set:

1 x ORIGINAL PDE bridge (pump-nozzle-unit-bridge)

5 x reinforced VITON gasket set

1 x PDE cable set / PDE wiring harness for 5-cylinder

1 x PDE mounting kit for 5-cylinder

for VW T5 2.5 TDI (all code letters)

Selected products

-

07eins Turbocharger for Volkswagen T5 2.5 TDI

Normal price 949,00€Normal priceBase price per999,00€Selling price 949,00€Offer