PDE seals must be replaced during diesel engine overhaul: Background on reinforced VITON sealing rings

Due to the operating principle of the 07eins reinforced VITON sealing rings for the maintenance and repair of cylinder heads in TDI diesel pump-injector engines of the Volkswagen Group (VW, Audi, Skoda and Seat), especially in combination with with the 07eins ORIGINAL PDE body holders (repair holders) or the 07eins ORIGINAL PDE bridge future cylinder head damage is sustainably avoided. The oversize VITON gaskets from 07eins represent the optimum complementary solution for unit injector engines to prevent cylinder head damage.

Technical background for the necessity of replacing the old sealing rings and the use of 07eins reinforced VITON sealing rings:

Our mechanical systems to improve the assembly and positioning of the PDE, such as. 07eins PDE body holder (repair holder) and 07eins PDE bridge, form the basis for a technically flawless function of the injection on the TDI engines, up to very high mileages of the engines. The technical principle of operation of the 07eins PDE body holder is described in our blogpost "Avoidance of cylinder head damage in unit injector TDI engines: Optimum problem solution with 07eins PDE body holders" explained in detail.

The highly stressed sealing rings on the unit injectors play an equally important role in improving the injection system and its reliable sealing. Under extreme temperature fluctuations, vibrations and in direct contact with fuel and engine oil, these seals must keep the pressurized diesel circuit separate from the oil circuit. If these seals fail, oil dilution takes place as a result of diesel mixing into the engine oil. Unnoticed, the oil rapidly loses its lubricating ability, which often leads to severe engine damage during further operation. Without proper lubrication, crankshaft bearing shells, connecting rod bearings, camshafts, hydraulic tappets, center bearings of the turbocharger and, last but not least, cylinder liners, pistons and piston rings wear out within a very short time.

The necessity of replacing the old sealing rings during maintenance and repair of cylinder heads: What can new seals now do better than the old ones?

One argument in favor of new sealing rings is that they harden over time due to lost plasticizers and are thus no longer pliable enough for consistent function. A far more important factor, especially for unit injector engines, is described in the following:

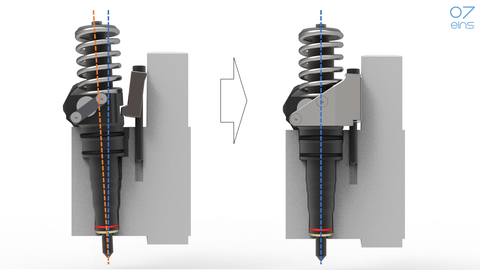

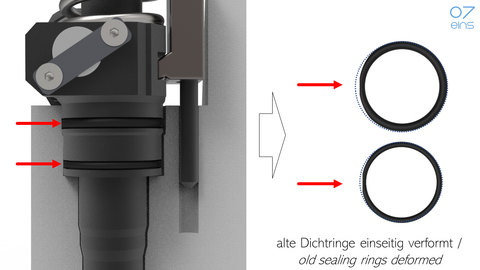

Due to years of one-sided assembly (see blogpost "Avoiding cylinder head damage in unit injector TDI engines: Optimum problem solution with 07eins PDE body holder"), the gaskets are always significantly more squeezed on one side than on the other. The sealing ring on the opposite side of the mounting screw is thereby almost invariably compressed, while the opposite side only lightly touches the cylinder head wall:

If a PDE bridge or PDE body holder is installed, the injector will again be clean and centered in its seal seat as originally intended. It is now important to ensure a uniform and clean seal seat by means of the new and undeformed sealing rings. Improved and aligned in this way, the PDE can ideally compensate for the thermal expansion and vibrations that occur, while ensuring perfect separation of oil and diesel at all times.

So why use 07eins reinforced VITON sealing rings?

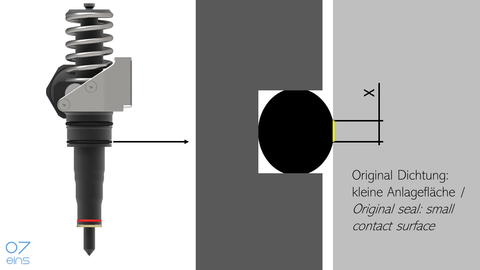

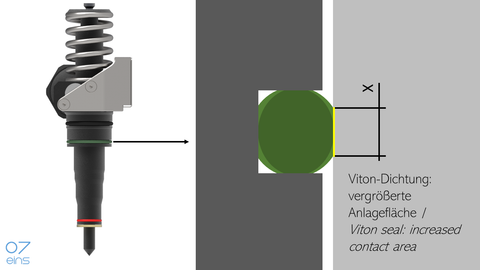

In addition to the already significantly higher resistance of the base material to intense heat and fuel, our reinforced VITON sealing rings have two important differences compared to standard seals, the combination of which accounts for the real success of these PDE seals:

First, the shear diameter of the seal ring is increased. Actually a logical measure: thicker gasket - keeps better tight. But in this case it is not quite so simple: a thicker sealing cord means that, when installed, significantly more material has to be accommodated in the groove provided. This creates a high load on the seal and sealing surface, which are constantly "under tension" with the pressed-in material. In extreme cases, this leads to the gasket material itself developing internal cracks and starting to literally disintegrate over time.

This is where the second important factor comes into play: the Shore hardness of the gasket material. In short, this key figure describes how soft a material is, or in a broader sense, how well it can be deformed.

With our selection of VITON rings, we rely on a combination of softer Shore hardness paired with an increased diameter. With this mixture, it is possible for the sealing rings to ideally fill the given sealing groove and thereby achieve the largest possible sealing contact area without being destroyed by excessive internal stresses of a hard sealing material.

This increased contact surface is also the reason why the 07eins reinforced VITON gasket rings are recommended above all for cylinder heads with deeper run-in marks. Existing "scratches" can simply be covered better and sealed more reliably with the wider contact surface.

For the maintenance and repair of cylinder heads in TDI diesel pump-injector engines of the Volkswagen Group (VW, Audi, Skoda and Seat), 07eins reinforced VITON sealing rings are suitable due to a balanced combination of soft Shore hardness and enlarged ring diameter, especially in combination with the 07eins ORIGINAL PDE body holders (repair holders) or the 07eins ORIGINAL PDE bridge. This sustainably prevents cylinder head damage in TDI engines.