Prevention of cylinder head damage in pump-injector element TDI engines: Optimum problem solving through 07eins PDE body holder

Cylinder head damage in TDI engines from the Volkswagen Group (VW, Audi, Skoda and Seat) with pump injector elements ("PDE") built between 1998 and 2010 is often caused by loose PDE seats, which work their way into the cylinder head and can lead to leaks and even cylinder head damage. The ORIGINAL 07eins PDE body holder (repair holder) solve the problem sustainably and permanently, unlike competitor products. This makes defective cylinder heads in TDI diesel engines a thing of the past. In combination with the 07eins reinforced VITON sealing rings, diesel engines receive maximum protection against fuel mixing into the oil circuit.

A detailed overview of the 07eins PDE body mounts is available at Pump nozzle unit body holder / PDE repair holder for VW, Audi, Seat, Skoda TDI to find.

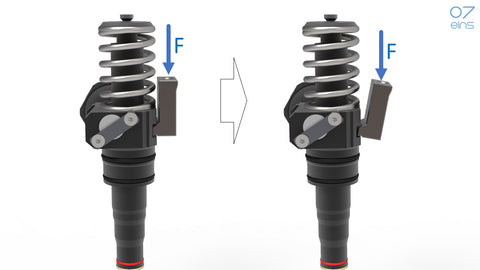

Technical cause of the pump-nozzle problemThe damage ("run-in marks") in the seats of the Bosch pump-nozzle injectors bolted on one side, which only occur in the cylinder head on the opposite side of the screw connection, are caused by the original retaining shoes tilting sideways when they are tightened.

The force caused by the one-sided screwing of the retaining shoes presses the PDEs onto the opposite inside of the PDE seats, because the engagement in the groove on the injector is at some distance next to the screw connection:

Non-optimal cause avoidance by VW for TDI pump injector element engines with higher mileage

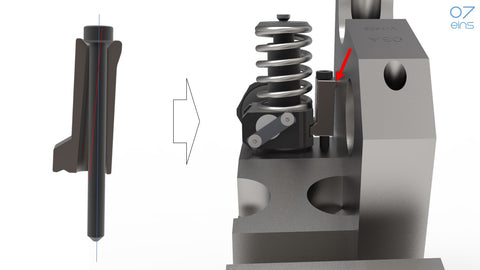

VW also took this problem into account from the outset and, on closer inspection, provided the retaining shoes with a protrusion at their upper edge, with which the holder is supported against tilting on the cylinder head. In addition, the bore was widened at the bottom to prevent the bolt from being subjected to a bending moment.

During the development of the PDE TDI engines at that time, it was obviously not possible to correctly estimate the extent of this resulting support force, which always leaves tangible and visible marks on this support surface on every cylinder head, over the service life of the TDI engines:

The counterpart of these worn surfaces are the injector seats, which now have to withstand the transverse force applied. In the course of operation under alternating heat and cold and vibration, the pump-nozzle injectors work their way more and more into the cylinder head. After a long period of operation, this leads to diesel interference and the resulting numerous consequential damages and engine running problems, including complete cylinder head damage.

Non-optimal problem solution of the competitor product for TDI pump-nozzle element engines with higher mileage

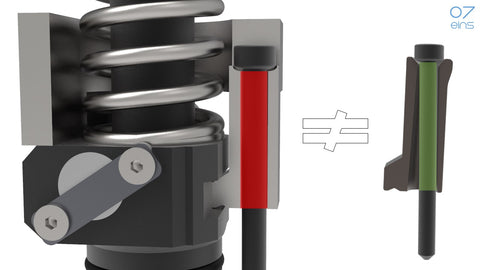

If a loose bracket with an extended base is now used on the other side of the injector, it will experience the same tilting moment as the original retaining shoes (the groove and support are still offset to the side of the fastening screw).

Optimum problem solution with the ORIGINAL 07eins PDE body holder (repair holder) with support plates

To counteract tilting, the screw in a narrow bore must absorb the force that is normally transferred to the cylinder head.

The injector screw, which is already subject to high loads, is not designed for this type of force transmission. This overload can lead to complete cylinder head damage with prolonged running time and additional vibrations and thermal expansion.

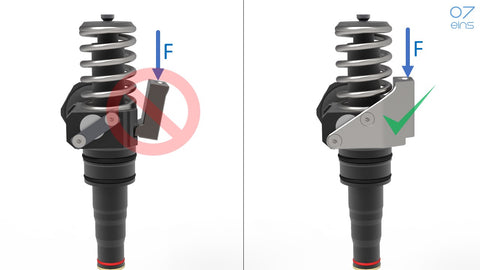

During the development of the 07eins PDE body holders, this problem was taken into account:

By screwing the body holder to the injector, a frictional connection is created to the pump-nozzle element. As a result, the tilting force is transferred to the body of the injector via the screwed wing.

07eins PDE body holders (repair holders) eliminate the cause of cylinder head damage in TDI engines with pump-injector elements sustainably and permanently:

The bore hole for the expansion screw is 07eins PDE body holders, as in the VW original, is so large that there is no contact and therefore no bending force transmission to the thread.

This technical solution for the connection with the pump-nozzle element is protected by DE utility model DE 20 2020 106 341 U1. For this reason, competitor products CANNOT use this optimum connection of PDE and repair holder.

But that's not all. The transverse force that has now been described several times is prevented with the connection to the PDE body. Nevertheless, there is still "only" a one-sided screw connection without actual centering of the injector (as is also the case with surface-mounted solutions, of course).

Another advantage of using the 07eins PDE body holders is that additional support plates are used to provide additional support.

Each cylinder head has a known, exact dimension of the side cylinder wall to the center of the PDE seat. The corresponding surface is machined and brought to size on each cylinder. As described above, VW also used these surfaces to support the retaining shoes.

The 07eins PDE body holders use this precise contact surface and create a tolerance-compliant support connection with exact centering of the PDE by applying this support gauge block.

Summary

The protected ORIGINAL 07eins PDE body holders eliminate the problem of TDI engines with pump-injector injectors built between 1998 and 2010 thanks to the friction-locked screw connection with the pump-injector element. Solutions with one-piece body holders or repair holders do not offer this lasting and permanent protection.